In the world of plastic molding, innovation is key to staying ahead of the competition and meeting the ever-evolving needs of customers. One of the latest innovations in the industry is Nylon Injection Molding which has been gaining traction as a viable option for various applications. With its unique properties and durability, nylon injection molding is revolutionizing the way plastic products are manufactured.

Nylon injection molding is a process that involves injecting molten nylon material into a mold cavity under high pressure. The result is a product that is strong, flexible, and resistant to abrasion, making it an ideal choice for a wide range of applications. From automotive parts to household products, nylon injection molding has proven to be a versatile and reliable option for manufacturers looking to create high-quality, durable products.

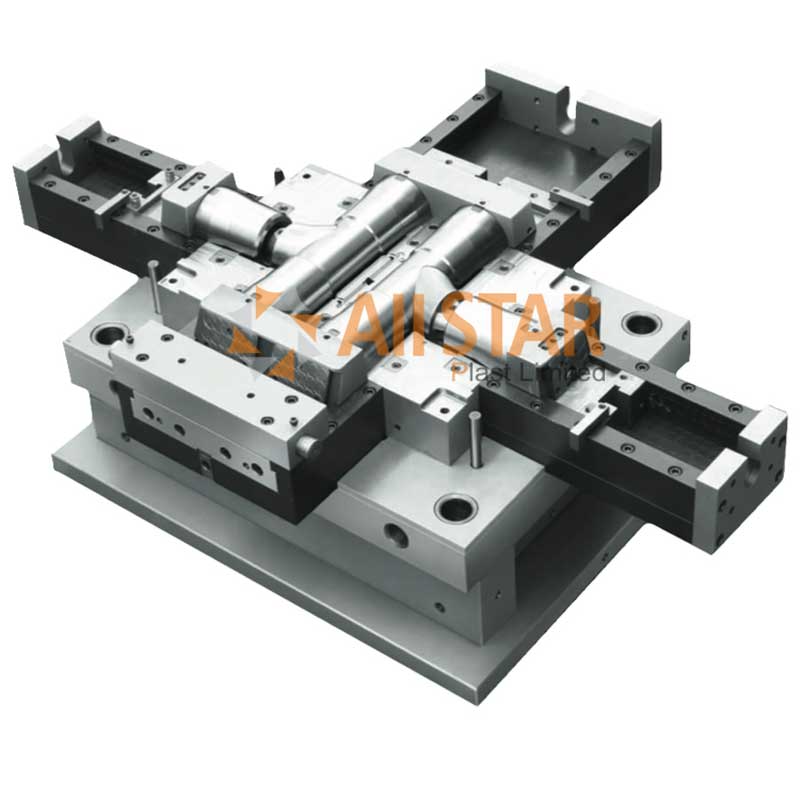

One company at the forefront of nylon injection molding is ALL STAR PLAST, one of the most vibrant and reliable plastic mold manufacturers in China. With a focus on automotive mold, household products mold, home appliance mold, and packaging mold, ALL STAR PLAST has a history of over 15 years in the industry, making them a trusted and experienced partner for manufacturers looking to leverage the benefits of nylon injection molding.

One of the key advantages of nylon injection molding is its ability to produce parts with high strength and toughness. This makes it an ideal choice for automotive applications, where parts need to withstand heavy usage and extreme conditions. With the ability to produce bumper, fender, and decoration panel molds, ALL STAR PLAST is well-equipped to meet the needs of the automotive industry with their nylon injection molding capabilities.

In addition to automotive applications, nylon injection molding is also making an impact in the household products and home appliance industries. With its resistance to abrasion and flexibility, nylon injection molded parts are ideal for products that are used frequently and subjected to wear and tear. From kitchen utensils to electrical components, manufacturers are turning to nylon injection molding as a reliable and cost-effective solution for creating durable and long-lasting products.

Furthermore, the packaging industry is also benefiting from nylon injection molding, as the material's strength and flexibility make it well-suited for creating durable and impact-resistant packaging solutions. With the ability to create custom molds for packaging products, ALL STAR PLAST is well-equipped to meet the unique and demanding requirements of the packaging industry with their nylon injection molding expertise.

The increasing demand for nylon injection molding is also being driven by the growing focus on sustainability and recyclability. Nylon is a highly recyclable material, making it an environmentally friendly choice for manufacturers looking to reduce their environmental impact. With an increasing emphasis on sustainable manufacturing practices, nylon injection molding is emerging as a popular and responsible choice for creating plastic products.

With its ability to produce high-strength, durable, and recyclable products, nylon injection molding is proving to be a game-changer in the plastic molding industry. As one of the leading plastic mold manufacturers in China, ALL STAR PLAST is well-positioned to capitalize on the growing demand for nylon injection molding and deliver innovative solutions to their customers.

In conclusion, nylon injection molding is revolutionizing the way plastic products are manufactured, with its unique properties and versatility making it a popular choice for a wide range of applications. With their expertise and experience in automotive, household products, home appliance, and packaging mold manufacturing, ALL STAR PLAST is at the forefront of the nylon injection molding revolution, providing manufacturers with high-quality, durable, and sustainable products. As the industry continues to evolve, nylon injection molding is set to play a vital role in driving innovation and meeting the needs of a rapidly changing market.