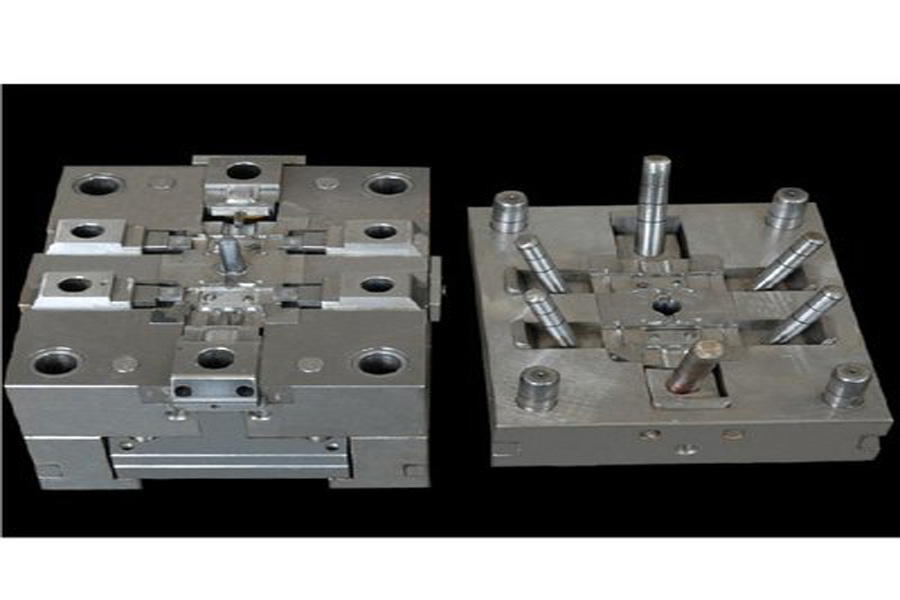

Die casting, also known as pressure die casting, is a manufacturing process in which molten metal is injected into a mold or die under high pressure. This process is widely used in the manufacturing industry to produce high-quality and complex components with accurate dimensions and intricate geometries.

At ALL STAR PLAST, we understand the significance of die casting in the manufacturing industry, and we have been providing high-quality die cast products to our clients for over 15 years. Our die cast products are used in a variety of industries, including automotive, aerospace, electronics, and consumer products.

In the automotive industry, die casting is used to produce components such as engine blocks, transmission housings, and brake systems. These components require high strength, durability, and precision, which can be achieved through die casting. With advancements in die casting technology, automotive manufacturers can now produce lightweight components that improve fuel efficiency and reduce emissions.

The aerospace industry also relies heavily on die casting to produce components such as turbine blades, engine parts, and structural components. These components require high strength-to-weight ratios, which can be achieved through die casting. Die casting also allows for the production of components with intricate geometries that cannot be achieved through other manufacturing processes.

Die casting is also widely used in the electronics industry to produce components such as heat sinks, connectors, and enclosures. These components require high thermal conductivity, electrical conductivity, and corrosion resistance, which can be achieved through die casting. Die casting also allows for the production of components with complex shapes and designs that cannot be achieved through other manufacturing processes.

In the consumer products industry, die casting is used to produce components such as toys, kitchen utensils, and electronic devices. These components require high precision and a smooth surface finish, which can be achieved through die casting. Die casting also allows for the production of components in large quantities, making it a cost-effective and efficient manufacturing process.

At ALL STAR PLAST, we have invested in advanced die casting equipment and technology to ensure that we can deliver high-quality die cast products to our clients. Our team of experienced engineers and technicians work closely with our clients to understand their specific requirements and develop customized solutions to meet their needs.

In conclusion, die casting plays a critical role in the manufacturing industry, and its importance cannot be overstated. As the demand for high-quality, complex, and precise components continues to grow, die casting will continue to be a vital manufacturing process. At ALL STAR PLAST, we are committed to providing our clients with high-quality die cast products that meet their specific requirements and exceed their expectations.