Injection Molding: A Vital Component of Modern Manufacturing

The invention of injection molding has been one of the most significant milestones in the history of manufacturing. It has revolutionized the way we produce plastic parts, making it possible to create complex, precise shapes with high efficiency and accuracy.

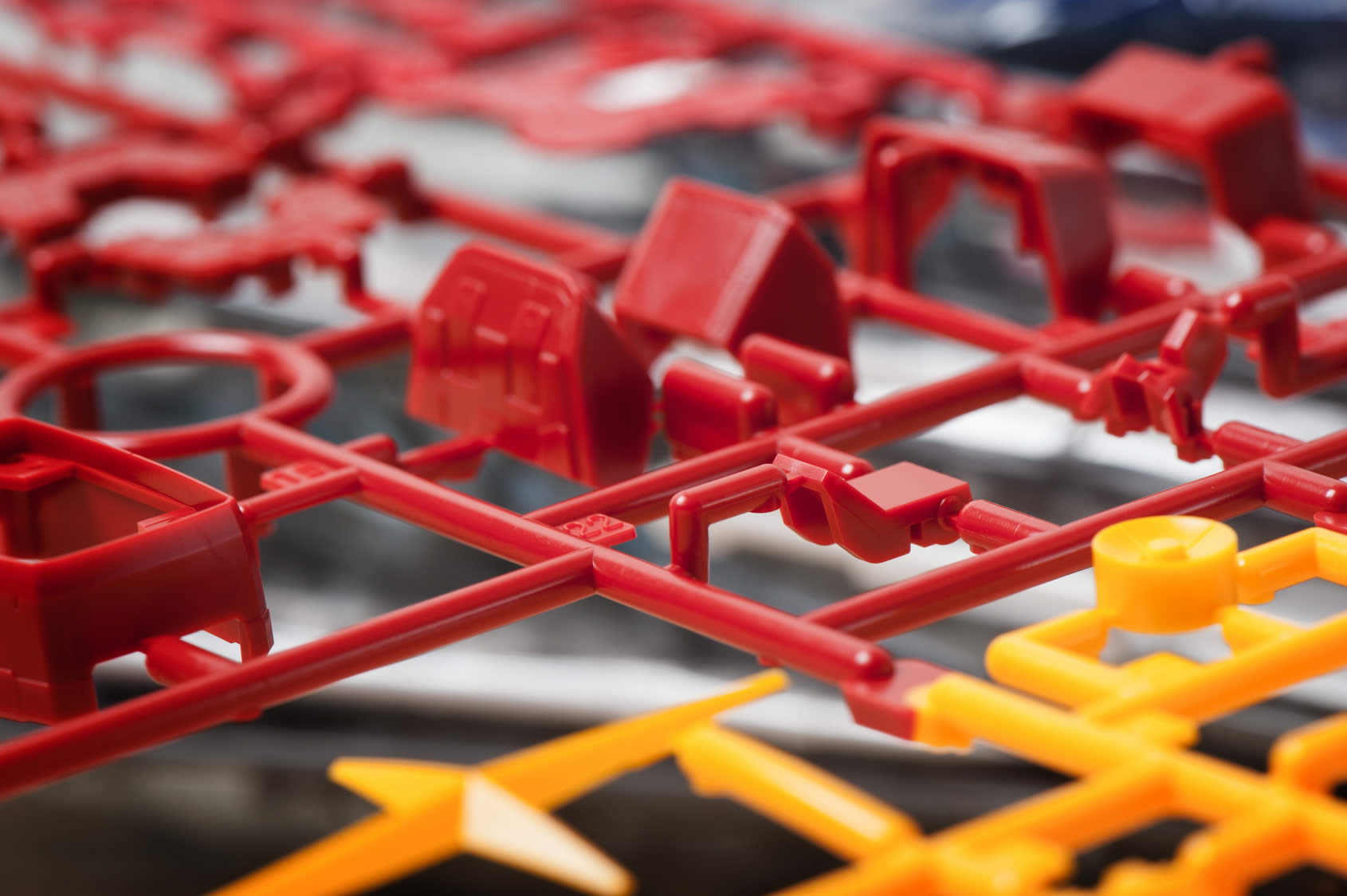

Injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity, where it cools and solidifies into the desired shape. This process is highly automated and can be used to produce large quantities of identical parts quickly and cost-effectively.

The versatility and efficiency of injection molding have made it a popular choice for a wide range of applications, from simple toys and household items to intricate medical devices and automotive components. In fact, nearly one-third of all plastic parts manufactured today are made using injection molding.

At Sussex IM, we are proud to be at the forefront of this important technology. With over 65 injection molding machines ranging from 25 to 725 tons, we have the capacity and expertise to handle mid to high-volume production runs of any size and complexity.

Our team has experience processing over 100 engineering-grade performance resins, including thermoplastics, thermosets, and elastomers. We have the knowledge and skills to help our clients choose the right material for their specific application, ensuring optimal performance, durability, and cost-effectiveness.

One of the key advantages of injection molding is its ability to produce consistent, high-quality parts with minimal waste. This is achieved through precise control of temperature, pressure, and injection speed, as well as the use of advanced robotics and automation systems.

Moreover, injection molding allows for the creation of complex geometries and features that would be impossible or costly to achieve using other manufacturing methods. This includes intricate details such as undercuts, threads, and fine surface textures.

At Sussex IM, we take pride in our ability to provide end-to-end solutions for our clients, from design and prototyping to tooling and production. Our manufacturing floor is equipped with state-of-the-art machinery, including (need remove brand name), which allows us to produce high-quality, precision parts with unmatched efficiency and accuracy.

As the demand for lightweight, durable, and sustainable materials continues to grow, injection molding is poised to play an even more significant role in the future of manufacturing. With its versatility, efficiency, and cost-effectiveness, it offers immense potential for innovation and growth in a wide range of industries, from automotive and aerospace to healthcare and consumer goods.

Importantly, injection molding is also a highly sustainable manufacturing process, as it allows for the use of recycled and biodegradable materials, as well as the reduction of waste and energy consumption. This makes it an ideal choice for companies looking to reduce their environmental impact and meet their sustainability goals.

In conclusion, injection molding is a vital component of modern manufacturing, offering unmatched versatility, efficiency, and cost-effectiveness for the production of plastic parts. At Sussex IM, we are proud to be part of this important industry and to help our clients bring their ideas to life with high-quality, precision parts that meet their specific needs and requirements.

As the world continues to evolve and demand for innovative solutions grows, we look forward to being at the forefront of this exciting field, pushing the boundaries of what is possible and making a positive impact on our industry and our planet.